- Sustainability

- Eco-design Products

Eco-design Products

The Tamura Group carries out product environmental assessment in the development and design phases to minimize environmental impact, and strives to contribute to achieving a sustainable society through the development and provision of products that contribute to sustainability.

The Tamura Group carries out product environmental assessment (based on our own criteria) in the development and design phases to reduce the environmental burden, and strives to contribute to achieving a sustainable society through the development and provision of products that contribute to sustainability.

In FY 2023, the sales ratio was 24%, achieving the target of 24%.

We will continue to contribute to reducing environmental impact through further development and provision.

Lineup of Products that Contribute to Sustainability

Electronic components

Electronic chemicals

FA systems

Information equipment

Electronic components

Electronic chemicals

FA systems

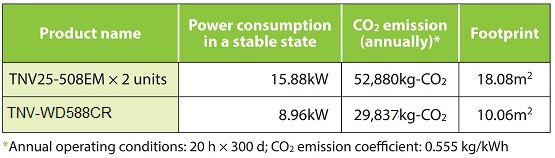

◆Energy-saving N2 dual-reflow system (TNV-WD588CR)

A new N2 dual-reflow system with a dual lane conveyor mechanism has been added to the TNV series that has already been employed as energy-saving reflow systems by users. The N2 dual-reflow system has a two-lane conveyor that allows PCB mounting without relying on other systems, as the PCB mounting process typically requires two systems. It has the same time-tested energy-saving thermal insulation structure as the TNV series, thereby reducing power consumption by about 45% compared with two single-lane TNV systems. It also reduces footprint by about 45%. It has been adopted mainly by users associated with in-car products.

Information equipment

The Tamura Group carries out product environmental assessment (based on our own criteria) in the development and design phases to reduce the environmental burden, and strives to contribute to achieving a sustainable society through the development and provision of products that contribute to sustainability.

In FY 2023, the sales ratio was 24%, achieving the target of 24%.

We will continue to contribute to reducing environmental impact through further development and provision.

Products that Contribute to Sustainability

◆Heat dissipation ferrite (HDF) switching transformers that reduce the near magnetic field by 50%

High-capacity switching transformers used in power conditioners and fast EV chargers face demands for smaller size, higher efficiency, and higher frequency. There is also a growing need for solutions to the resulting effects of near magnetic field noise on peripheral components. Moreover, the dual active bridge (DAB) converter circuits and LLC converter circuits frequently used in recent years employ resonance coils to extract the leakage inductance required in circuits, a factor in cost increases.

HDF switching transformers, developed to solve these problems, adopt a unique core shape to reduce the near magnetic field by 50%, achieving superior heat dissipation, small size, and high density. They adopt a split coil structure capable of reducing the magnetic coupling area between the primary and secondary windings, which easily enables optimal leakage inductance of about 10-20% leakage in circuits. This eliminates the need for resonant coils in circuits, which reduces costs, shrinks the installation footprint, and enables the miniaturization of devices.

High-capacity switching transformers used in power conditioners and fast EV chargers face demands for smaller size, higher efficiency, and higher frequency. There is also a growing need for solutions to the resulting effects of near magnetic field noise on peripheral components. Moreover, the dual active bridge (DAB) converter circuits and LLC converter circuits frequently used in recent years employ resonance coils to extract the leakage inductance required in circuits, a factor in cost increases.

HDF switching transformers, developed to solve these problems, adopt a unique core shape to reduce the near magnetic field by 50%, achieving superior heat dissipation, small size, and high density. They adopt a split coil structure capable of reducing the magnetic coupling area between the primary and secondary windings, which easily enables optimal leakage inductance of about 10-20% leakage in circuits. This eliminates the need for resonant coils in circuits, which reduces costs, shrinks the installation footprint, and enables the miniaturization of devices.

|

|

◆TLF407-LT01 solder for low-melting-point mounting (solder paste)

Amid growing interest in the sustainability of the global environment, low-melting-point solder that reduces the environmental impact of processes is coming under attention. Compared to conventional SAC305 (Sn-3Ag-0.5Cu) solder widely used in the market, the melting temperature of Sn-Bi-based solder is somewhat lower than its profile temperature, enabling reduced power consumption in the reflow process. Our estimates suggest a 40% reduction in annual power consumption.

Our new TLF407-LT01 uses a new alloy (Sn-Bi+α) that offers improved resistance to drop impact, an issue with Sn-Bi-based lowmelting-point solder. It can also be used in atmospheric reflow processes that do not use nitrogen, reducing power consumption while contributing to reduced environmental impact.

Amid growing interest in the sustainability of the global environment, low-melting-point solder that reduces the environmental impact of processes is coming under attention. Compared to conventional SAC305 (Sn-3Ag-0.5Cu) solder widely used in the market, the melting temperature of Sn-Bi-based solder is somewhat lower than its profile temperature, enabling reduced power consumption in the reflow process. Our estimates suggest a 40% reduction in annual power consumption.

Our new TLF407-LT01 uses a new alloy (Sn-Bi+α) that offers improved resistance to drop impact, an issue with Sn-Bi-based lowmelting-point solder. It can also be used in atmospheric reflow processes that do not use nitrogen, reducing power consumption while contributing to reduced environmental impact.

|

|

Lineup of Products that Contribute to Sustainability

Electronic components

Electronic chemicals

FA systems

Information equipment

|

|

Lineup of Products that Contribute to Sustainability

|

Electronic components

◆Power Modules (xPM series)

Since regulations on energy conservation are being tightened to achieve carbon neutrality, there is a growing demand for power sources that offer high-efficiency.

Our energy-saving power modules (xPM series) is comprised of five series, from 3 to 80 W class, and can be selected according to power and voltage levels. In addition, the module has significantly improved power consumption characteristics under no load and efficiency characteristics under light load (when the product is in a standby state). This series responds to the energysaving issues of customers and contributes to the reduction of power consumption and the reduction of man-hours for product development.

Since regulations on energy conservation are being tightened to achieve carbon neutrality, there is a growing demand for power sources that offer high-efficiency.

Our energy-saving power modules (xPM series) is comprised of five series, from 3 to 80 W class, and can be selected according to power and voltage levels. In addition, the module has significantly improved power consumption characteristics under no load and efficiency characteristics under light load (when the product is in a standby state). This series responds to the energysaving issues of customers and contributes to the reduction of power consumption and the reduction of man-hours for product development.

|

|

◆Compact Low-frequency Reactor with Newly Designed Structure

Low-frequency reactors are installed in air conditioners as well as in other various inverter devices and are key components essential for efficient control of the devices.

Low-frequency reactors are installed in air conditioners as well as in other various inverter devices and are key components essential for efficient control of the devices.

For this product, CAE technology was utilized to partially revise the existing product structure and realize the following.

1) A unique gap shape (patent pending) makes the body smaller, lighter (approx. 30% lighter), and less expensive.

2) A new terminal structure to reduce the volume of the connection to the device by more than 20%.We contribute to the improvement of production efficiency, energy saving, and resource saving at our customers.

|

|

◆Gate driver modules: 2DUD_P series and 2LG series

The 2DUD_P series and the 2LG series are gate drivers compatible with high-voltage/ high-current IGBT and SiC-MOSFET (1700 V/1800 A class), suitable for 2 MW class solar power generation and wind power generation systems.

Tamura's unique “low-capacitive coupling, insulated DC-DC converter,” “low-impedance drive circuit,” and “structural design that minimizes gate wiring” enable stable gate drive even in switching operations exceeding 3,000 A. In addition, they are equipped with a short-circuit protection function that can safely stop operation even for a short-circuit current of 10,000 A or higher via DESAT detection and soft turn-off. They are also equipped with important functions, such as active clamps, UVLOs, and mirror clamps, for driving IGBTs and SiC-MOSFETs.

These functions will improve the reliability and design efficiency of the entire system developed by the customer. Furthermore, they will contribute to the stable supply of renewable energy, for which needs are accelerating toward the realization of carbon neutrality.

The 2DUD_P series and the 2LG series are gate drivers compatible with high-voltage/ high-current IGBT and SiC-MOSFET (1700 V/1800 A class), suitable for 2 MW class solar power generation and wind power generation systems.

Tamura's unique “low-capacitive coupling, insulated DC-DC converter,” “low-impedance drive circuit,” and “structural design that minimizes gate wiring” enable stable gate drive even in switching operations exceeding 3,000 A. In addition, they are equipped with a short-circuit protection function that can safely stop operation even for a short-circuit current of 10,000 A or higher via DESAT detection and soft turn-off. They are also equipped with important functions, such as active clamps, UVLOs, and mirror clamps, for driving IGBTs and SiC-MOSFETs.

These functions will improve the reliability and design efficiency of the entire system developed by the customer. Furthermore, they will contribute to the stable supply of renewable energy, for which needs are accelerating toward the realization of carbon neutrality.

|

|

◆Open-loop high-current sensor L40S/L51S series

The L40S and L51S series consist of open-loop high-current sensors for renewable energy systems, such as solar and wind power generation systems, and for energy management systems, such as electricity storage systems.

With a temperature compensation circuit, the sensors achieve a linearity error of 1% and an output temperature characteristic of 0.05%/°C over the wide temperature range of -40 to 105°C. They are therefore suitable for accurate control of a system exposed to a severe natural environment. In addition, their shield technology achieves noise resistance properties such as dV/dt at least three times as high as those of our existing products. Moreover, by devising the design of its casing structure, the L51S series can reduce the amount of filler by 20% compared with existing products, to help reduce environmental load.

The L40S and L51S series consist of open-loop high-current sensors for renewable energy systems, such as solar and wind power generation systems, and for energy management systems, such as electricity storage systems.

With a temperature compensation circuit, the sensors achieve a linearity error of 1% and an output temperature characteristic of 0.05%/°C over the wide temperature range of -40 to 105°C. They are therefore suitable for accurate control of a system exposed to a severe natural environment. In addition, their shield technology achieves noise resistance properties such as dV/dt at least three times as high as those of our existing products. Moreover, by devising the design of its casing structure, the L51S series can reduce the amount of filler by 20% compared with existing products, to help reduce environmental load.

|

|

◆High-frequency reactor for resonance L circuits and boundary-current mode, having high efficiency and high performance

A circuit that causes loss in a reactor, such as a resonance circuit or a critical mode, is increasingly used in energy, air conditioning, and various other fields. This product features a low-loss ferrite core and an edgewise coil that minimizes high-frequency loss.

In addition, the division of gaps reduces loss due to flux leakage from the gaps. Magnetic-field analysis has been utilized effectively for the optimization of this gap configuration. The structure and configuration of the reactor were examined in this way, and further loss reduction and energy saving were achieved.

A circuit that causes loss in a reactor, such as a resonance circuit or a critical mode, is increasingly used in energy, air conditioning, and various other fields. This product features a low-loss ferrite core and an edgewise coil that minimizes high-frequency loss.

In addition, the division of gaps reduces loss due to flux leakage from the gaps. Magnetic-field analysis has been utilized effectively for the optimization of this gap configuration. The structure and configuration of the reactor were examined in this way, and further loss reduction and energy saving were achieved.

|

|

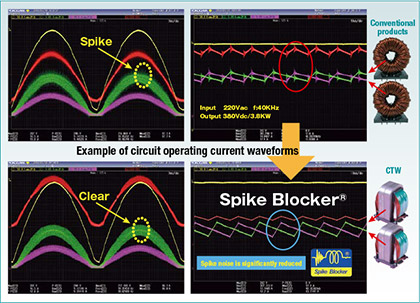

◆CTW series-high-efficiency, low-cost, high-performance reactors for PFC

All industries have been stepping up their efforts for energy saving year by year. The CTW series is Tamura's unique product developed as components for PFC (Power Factor Correction) circuits used to ensure energy saving in various devices. It features: 1) Hybrid technology and optimized structure (contributing to saving energy and resources by combining different iron core materials to optimize their properties and by minimizing the use of materials other than electrical wire and iron cores, which are main materials); and 2) Spike Blocker® technology (contributing to saving energy and resources by minimizing spike noise (the figure on the right) to reduce the number of peripheral circuit components).

All industries have been stepping up their efforts for energy saving year by year. The CTW series is Tamura's unique product developed as components for PFC (Power Factor Correction) circuits used to ensure energy saving in various devices. It features: 1) Hybrid technology and optimized structure (contributing to saving energy and resources by combining different iron core materials to optimize their properties and by minimizing the use of materials other than electrical wire and iron cores, which are main materials); and 2) Spike Blocker® technology (contributing to saving energy and resources by minimizing spike noise (the figure on the right) to reduce the number of peripheral circuit components).

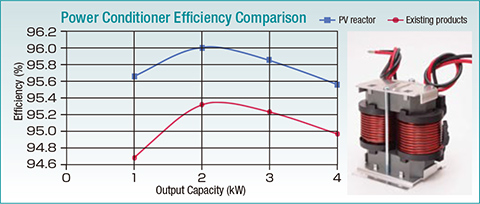

◆High-performance PV Reactors for Solar Power Generation

An electric power converter (power conditioner) that is used for solar power generation incorporates advanced technologies for maximizing the power conversion efficiency. We produced a catalogue of 108 variations of a PV reactor created by standardizing a reactor that is built into the electric power converter. The features are as follows: 1) A hybrid technology in which cores made of different materials are combined, 2) Spike-blocker technology for minimizing spike noise to contribute to the electromagnetic compatibility of converters, 3) CB-reactor technology for operating two MPPTs with one reactor to contribute to improving the efficiency of a set of equipment. This PV reactor is a global standard reactor that Tamura offers with confidence.

An electric power converter (power conditioner) that is used for solar power generation incorporates advanced technologies for maximizing the power conversion efficiency. We produced a catalogue of 108 variations of a PV reactor created by standardizing a reactor that is built into the electric power converter. The features are as follows: 1) A hybrid technology in which cores made of different materials are combined, 2) Spike-blocker technology for minimizing spike noise to contribute to the electromagnetic compatibility of converters, 3) CB-reactor technology for operating two MPPTs with one reactor to contribute to improving the efficiency of a set of equipment. This PV reactor is a global standard reactor that Tamura offers with confidence.

◆Closed-loop-type current sensors applicable to large current: S30/S42 series

In the green energy market (wind power generation, solar power generation) that is sharply expanding worldwide, highly precise and reliable current sensors of the few-thousand-ampere class are demanded for DC/AC conversion control and supply current monitoring of power generation equipment.

In response to such demand, in addition to sharply reducing offset, realizing low-temperature drift, and reducing dv/dt output error of the S30 & S42 series, we have reduced their weight by 20% compared with the conventional product through the optimization of the core shape and thinning.

In the green energy market (wind power generation, solar power generation) that is sharply expanding worldwide, highly precise and reliable current sensors of the few-thousand-ampere class are demanded for DC/AC conversion control and supply current monitoring of power generation equipment.

In response to such demand, in addition to sharply reducing offset, realizing low-temperature drift, and reducing dv/dt output error of the S30 & S42 series, we have reduced their weight by 20% compared with the conventional product through the optimization of the core shape and thinning.

|

|

◆kW-class electric power source with ultra-high efficiency

A number of large-scale sports facilities for football, baseball, etc. are supplied with AC400V power source.

In the conventional method, the voltage of AC400V is lowered to AC200V with a voltage-reduction transformer. However, various disadvantages exist, such as a significant efficiency drop (approx. 90%) due to increased energy loss of the voltage-reduction transformer and heavy weight. This product has realized high efficiency and high power factor over a wide output range by directly controlling the voltage at AC400V without requiring a voltage-reduction transformer.

A number of large-scale sports facilities for football, baseball, etc. are supplied with AC400V power source.

In the conventional method, the voltage of AC400V is lowered to AC200V with a voltage-reduction transformer. However, various disadvantages exist, such as a significant efficiency drop (approx. 90%) due to increased energy loss of the voltage-reduction transformer and heavy weight. This product has realized high efficiency and high power factor over a wide output range by directly controlling the voltage at AC400V without requiring a voltage-reduction transformer.

|

|

|

◆Power modules (SPM, EPM, and BPM Series)

Laws and regulations requiring energy conservation are becoming increasingly strict on a global scale. Meanwhile, there are ever-growing demands for energy-saving power sources as manufacturers offer greater numbers of electric appliances whose additional value is environmentally conscious designs.

Tamura's high-efficiency power modules, namely, the SPM, EPM, and BPM Series, substantially improve power consumption characteristics at the time of no load, and efficiency characteristics at the time of light load (when products are in standby mode). These modules meet customers' need to develop products with the industry's highest level of energy conservation performance in a short period of time, thus helping reduce power consumption and development man-hours.

Laws and regulations requiring energy conservation are becoming increasingly strict on a global scale. Meanwhile, there are ever-growing demands for energy-saving power sources as manufacturers offer greater numbers of electric appliances whose additional value is environmentally conscious designs.

Tamura's high-efficiency power modules, namely, the SPM, EPM, and BPM Series, substantially improve power consumption characteristics at the time of no load, and efficiency characteristics at the time of light load (when products are in standby mode). These modules meet customers' need to develop products with the industry's highest level of energy conservation performance in a short period of time, thus helping reduce power consumption and development man-hours.

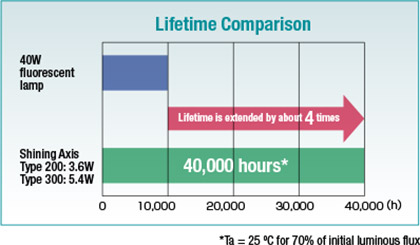

◆Advertisement lighting: Shining Axis-light source module for thin double-sided sign boards

Shining Axis is an LED light source for thin double-sided sign boards. Koha's original optical design allows the LED light source to be used in sign boards with a very small thickness (60 mm). Typically, thin double-sided sign boards use a light source with a light guide plate, and so they have low luminous efficacy and require high initial costs. Meanwhile, sign boards have been becoming thinner, and there is rapidly increasing demand for side-view type LED light sources that can respond to such market trend and can solve the problems with conventional light sources while ensuring uniform surface emission. Shining Axis, which uses special lenses developed by exploiting Koha's original optical design, is a new LED light source that minimizes unevenness in light emission from thin sign boards and has a better splash proof design (IPx4) than existing products. Also, the combination of two product models provides flexibility for a wide range of sign boards with various sizes. We have also commercialized optional connection parts for easier installation by utilizing our long experience in the sign board market.

Shining Axis is an LED light source for thin double-sided sign boards. Koha's original optical design allows the LED light source to be used in sign boards with a very small thickness (60 mm). Typically, thin double-sided sign boards use a light source with a light guide plate, and so they have low luminous efficacy and require high initial costs. Meanwhile, sign boards have been becoming thinner, and there is rapidly increasing demand for side-view type LED light sources that can respond to such market trend and can solve the problems with conventional light sources while ensuring uniform surface emission. Shining Axis, which uses special lenses developed by exploiting Koha's original optical design, is a new LED light source that minimizes unevenness in light emission from thin sign boards and has a better splash proof design (IPx4) than existing products. Also, the combination of two product models provides flexibility for a wide range of sign boards with various sizes. We have also commercialized optional connection parts for easier installation by utilizing our long experience in the sign board market.

Electronic chemicals

◆DSR-2200ACR-19M High-Reliability, Crack-Resistant Solder Resist for Automotive Use

The increasing popularity of eco-friendly cars (hybrid vehicles, electric vehicles, etc.) has ushered in an increase in the number of electronic control units (ECUs) installed in one car. To save space and reduce weight, the installation of ECUs in a harsher, higher-temperature environment is expected. Therefore, solder resist for PCBs used in ECUs needs to exhibit better resistance to a high-temperature environment.

This product is a matte-type alkaline development type soldermask for screen printing with improved high-temperature durability and low elasticity compared to conventional products, which significantly suppresses cracking in the solder mask in a thermal cycle test of -40°C ⇔ +160°C, which assumes a high-temperature environment, and has excellent high-temperature durability (160°C for 2,000 hours). It has high flexibility as well and can be used in PCBs that are bent when assembled (rigid flexible PCBs). It is a halogen-free product that contributes to space saving through the bending assembly.

The increasing popularity of eco-friendly cars (hybrid vehicles, electric vehicles, etc.) has ushered in an increase in the number of electronic control units (ECUs) installed in one car. To save space and reduce weight, the installation of ECUs in a harsher, higher-temperature environment is expected. Therefore, solder resist for PCBs used in ECUs needs to exhibit better resistance to a high-temperature environment.

This product is a matte-type alkaline development type soldermask for screen printing with improved high-temperature durability and low elasticity compared to conventional products, which significantly suppresses cracking in the solder mask in a thermal cycle test of -40°C ⇔ +160°C, which assumes a high-temperature environment, and has excellent high-temperature durability (160°C for 2,000 hours). It has high flexibility as well and can be used in PCBs that are bent when assembled (rigid flexible PCBs). It is a halogen-free product that contributes to space saving through the bending assembly.

|

|

◆White reflective material for LED mounting boards RPW-200 series and RPW-300 series

We have developed the RPW Series, which are white reflective material products that enhances the reflectivity of low-power, long-life LED lighting, contributing to higher brightness and longer life of LEDs.

For rigid PCBs, we have the RPW-200 Series, which achieves 92% reflectivity and heat discoloration resistance, and the RPW-300 Series for flexible substrates which achieves both high reflectivity and bendability.

We will continue to promote further development in anticipation of development in the LED field in the display and lighting markets.

|

|

◆Solder Paste for Fine Printing Designed for Mobile Devices

As mobile and wearable devices become smaller and thinner, substrates used in electronic devices are required to mount small electronic components at high density.

TLF204F-KSM has improved printability by using finer solder powder than conventional products in order to support high-density mounting. In the printing process, clogging is less likely to occur even after 3 hours of standing on the plate, and a reduction in the number of waste printing processes can be expected. In addition, because it has excellent cleaning performance for disposable substrates, it can be expected to reduce the number of cleaning steps and cleaning solvents.

Compared to conventional products, there is less viscosity change, the stencil life can be improved up to 72 hours, and the amount of solder paste waste can be reduced.

|

|

◆Solder paste using recycled Sn

TLF-204-27F4-R

Solder pastes TLF-204-27F4-R use tin that is refined and recycled from waste solder collected from customers. The “R” in the product name indicates Recycling.

The company has received the “Recycling Verification Statement” certified by SGS for both materials recycled after use in the production process (Post-Industrial) and materials recycled after use by the end consumer (Post-Consumer). These products are appropriate for resource recycling such as environmental regeneration and waste management for the realization of a sustainable society, toward which the movement is globally accelerating.

Solder pastes TLF-204-27F4-R use tin that is refined and recycled from waste solder collected from customers. The “R” in the product name indicates Recycling.

The company has received the “Recycling Verification Statement” certified by SGS for both materials recycled after use in the production process (Post-Industrial) and materials recycled after use by the end consumer (Post-Consumer). These products are appropriate for resource recycling such as environmental regeneration and waste management for the realization of a sustainable society, toward which the movement is globally accelerating.

|

|

◆Solder resist for flexible PCBs:

APB-300-32 series

As smartphones and wearable terminals become more sophisticated and lighter, flexible printed circuit boards (FPCs) are becoming more integrated and denser.

The black photo-developing solder resist APB-300-32 series for FPCs has realized strong adhesive bonding without the necessity of using connectors, and supports short-time pasting process by improving heat resistance and adhesiveness. Furthermore, in the FPC manufacturing process, high resolution has been achieved by low exposure (100 mJ/㎠), which is less than half of that in the company's conventional method. In the direct imaging exposure process, which is essential for high-density FPC processes, both high productivity and excellent resolution have been realized.

The product is halogen-free and therefore environmentally friendly, contributing to the development of advanced technology.

As smartphones and wearable terminals become more sophisticated and lighter, flexible printed circuit boards (FPCs) are becoming more integrated and denser.

The black photo-developing solder resist APB-300-32 series for FPCs has realized strong adhesive bonding without the necessity of using connectors, and supports short-time pasting process by improving heat resistance and adhesiveness. Furthermore, in the FPC manufacturing process, high resolution has been achieved by low exposure (100 mJ/㎠), which is less than half of that in the company's conventional method. In the direct imaging exposure process, which is essential for high-density FPC processes, both high productivity and excellent resolution have been realized.

The product is halogen-free and therefore environmentally friendly, contributing to the development of advanced technology.

|

|

◆TLF-TNA23 solder paste series compatible with 5G (5th generation mobile communications system)

5G base stations, the number of which is increasing rapidly, are often set up in a severe environment, such as an outdoor location, a high place, or a cold area. As such, a control system failure could affect all related wireless systems. In this regard, the solder paste used requires extremely high reliability.

The TLF-TNA23 series causes less migration because of its special halogen-free technology, even when the mounting location absorbs moisture. In addition, the series includes products combined with #287 alloy, which has sufficiently high strength (crack control) to withstand thermal shock due to high voltage.

It is an environmentally friendly, halogen-free, and leadfree product.

5G base stations, the number of which is increasing rapidly, are often set up in a severe environment, such as an outdoor location, a high place, or a cold area. As such, a control system failure could affect all related wireless systems. In this regard, the solder paste used requires extremely high reliability.

The TLF-TNA23 series causes less migration because of its special halogen-free technology, even when the mounting location absorbs moisture. In addition, the series includes products combined with #287 alloy, which has sufficiently high strength (crack control) to withstand thermal shock due to high voltage.

It is an environmentally friendly, halogen-free, and leadfree product.

|

|

◆APB-200 black solder resist series for rigid circuit boards for smartphones

As smartphones are becoming more functional, lighter, and thinner, their printed circuit boards are becoming increasingly integrated and dense.

The APB-200 black photoimageable solder resist series reduces lithographic exposure to one-third or less (100 mJ/cm2) compared with our existing products and offers high resolution in a lithographic exposure process for printed circuit board production, thereby achieving high productivity and good resolution in the direct-imaging lithographic exposure process necessary for high-density printed circuit boards.

Moreover, because of its less reflective appearance, it provides high visibility during automatic appearance inspection, resulting in good compatibility with high-density component mounting. It is an environmentally friendly halogen-free product.

As smartphones are becoming more functional, lighter, and thinner, their printed circuit boards are becoming increasingly integrated and dense.

The APB-200 black photoimageable solder resist series reduces lithographic exposure to one-third or less (100 mJ/cm2) compared with our existing products and offers high resolution in a lithographic exposure process for printed circuit board production, thereby achieving high productivity and good resolution in the direct-imaging lithographic exposure process necessary for high-density printed circuit boards.

Moreover, because of its less reflective appearance, it provides high visibility during automatic appearance inspection, resulting in good compatibility with high-density component mounting. It is an environmentally friendly halogen-free product.

|

|

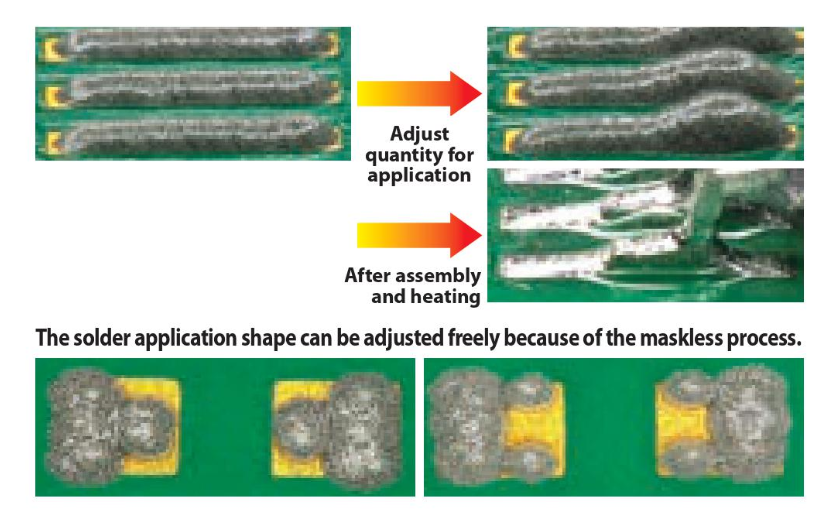

◆Jet-dispensing Pb-free solder pastes JDS204FMJ21-HF and JDS204G-MJ21-HF

These products use the solder composition of SAC305,which is Pb-free, and are regarded as halogen-free under the JPCA-ES01 standard. The use of jet dispensing as a contactless solder application process is being considered for solder supply to flexible printed circuit (FPC) boards, which are difficult to position by existing printing processes, and to circuit boards with cavities or three-dimensional circuit boards, which are very difficult to print by using a conventional printer. Currently, the JDS series offers two types of solder paste products according to the application diameter, and provides discharge stability and reduces scattering (satellite) during jet dispensing. Because it is treated in a contactless and maskless manner, no mask cleaning is needed, in contrast to a conventional assembly process. Therefore, it is an environmentally conscious product in terms of both characteristics and processes, helps meet the needs of next-generation customers, and responds to increasing environmental awareness.

These products use the solder composition of SAC305,which is Pb-free, and are regarded as halogen-free under the JPCA-ES01 standard. The use of jet dispensing as a contactless solder application process is being considered for solder supply to flexible printed circuit (FPC) boards, which are difficult to position by existing printing processes, and to circuit boards with cavities or three-dimensional circuit boards, which are very difficult to print by using a conventional printer. Currently, the JDS series offers two types of solder paste products according to the application diameter, and provides discharge stability and reduces scattering (satellite) during jet dispensing. Because it is treated in a contactless and maskless manner, no mask cleaning is needed, in contrast to a conventional assembly process. Therefore, it is an environmentally conscious product in terms of both characteristics and processes, helps meet the needs of next-generation customers, and responds to increasing environmental awareness.

◆General-purpose solder paste “TLF-204-HF35” compliant with halogen-free standard

This eco-design solder paste product has a Pb-free solder composition and also satisfies the “halogen-free” requirement that is specified by the JPCA-ES01 standard.

While a low working property has always been a problem for the conventional “halogen-free” product, this product has realized a combination of both high reliability and good working property.

The occurrence of voids and chip-side balls in leadless parts has increasingly become a problem with the increase in fine-components-mounted products on the market, which has been a very difficult problem for halogen-free paste. With the TLF-204-HF35, however, the Company has achieved a reduction of 50% in voids and chip-side balls compared with its conventional products.

Efforts will be made to expand the sales of this product that can respond to the needs of a wide range of customers.

This eco-design solder paste product has a Pb-free solder composition and also satisfies the “halogen-free” requirement that is specified by the JPCA-ES01 standard.

While a low working property has always been a problem for the conventional “halogen-free” product, this product has realized a combination of both high reliability and good working property.

The occurrence of voids and chip-side balls in leadless parts has increasingly become a problem with the increase in fine-components-mounted products on the market, which has been a very difficult problem for halogen-free paste. With the TLF-204-HF35, however, the Company has achieved a reduction of 50% in voids and chip-side balls compared with its conventional products.

Efforts will be made to expand the sales of this product that can respond to the needs of a wide range of customers.

|

|

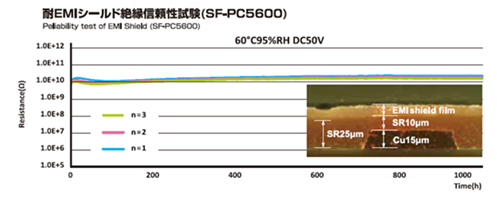

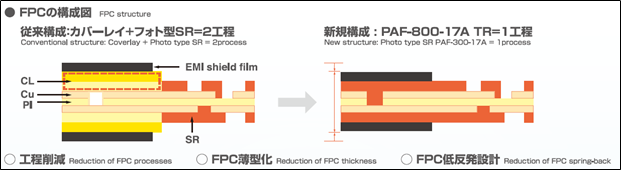

◆High-reliability and Low Spring-back Liquid-type Solder Resist “PAF-800-17A”

A solder resist for flexible printed circuit (FPC) boards, which realizes substantially enhanced insulation reliability in narrow gaps while maintaining flexibility. Because the solder resist provides high insulation in the thickness direction for standard thickness (10–20μm on copper wiring), EMI shielding film lamination on the resist surface is realized, which has been difficult to achieve in conventional products. By replacing the polyimide film coverlay that is currently used with the solder resist on FPC, this halogen-free product can also contribute to energy saving by reducing the FPC manufacturing process, to reducing FPC film thickness, and to space saving because its low spring-back property enables FPC to be installed even in a narrow space, such as the surroundings of a thin display.

A solder resist for flexible printed circuit (FPC) boards, which realizes substantially enhanced insulation reliability in narrow gaps while maintaining flexibility. Because the solder resist provides high insulation in the thickness direction for standard thickness (10–20μm on copper wiring), EMI shielding film lamination on the resist surface is realized, which has been difficult to achieve in conventional products. By replacing the polyimide film coverlay that is currently used with the solder resist on FPC, this halogen-free product can also contribute to energy saving by reducing the FPC manufacturing process, to reducing FPC film thickness, and to space saving because its low spring-back property enables FPC to be installed even in a narrow space, such as the surroundings of a thin display.

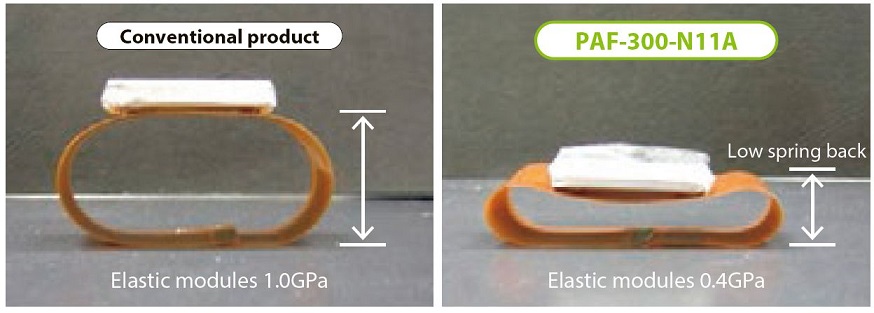

◆Low spring back solder resist (PAF-300-N11 series) for FPC

The PAF-300-N11 series of halogen-free solder resists for flexible substrates is available in various colors.

It is halogen-free and characterized by VTM-0 incombustibility. Due to its low-elasticity design, repulsion force is extremely low and the FPC substrate can be easily mounted by bending.

The PAF-300-N11 series of halogen-free solder resists for flexible substrates is available in various colors.

It is halogen-free and characterized by VTM-0 incombustibility. Due to its low-elasticity design, repulsion force is extremely low and the FPC substrate can be easily mounted by bending.

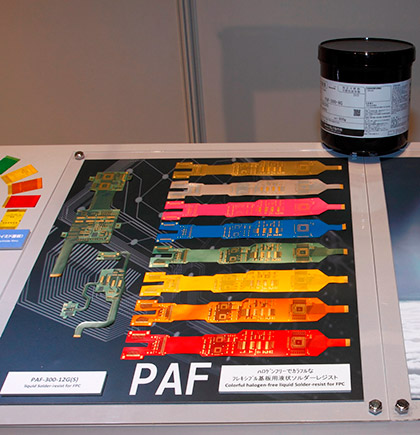

◆PAF-300 Series, solder resist for FPC

In recent years, there have been demands for smaller, thinner, lighter, and more sophisticated mobile equipment as typified by smartphones and wearable products, and demands for thinner and lighter printed circuit boards with components mounted at higher density have been also growing. For such electronic equipment, flexible printed circuits (FPCs) are increasingly being used.

In recent years, there have been demands for smaller, thinner, lighter, and more sophisticated mobile equipment as typified by smartphones and wearable products, and demands for thinner and lighter printed circuit boards with components mounted at higher density have been also growing. For such electronic equipment, flexible printed circuits (FPCs) are increasingly being used.

The PAF-300 Series meets the needs of customers who demand not only functions such as the flexibility required for FPC solder resist but also high design quality. It is a halogen-free, flame-resistant, safe, and functional solder resist product whose beautiful color never fades. It excels in flexibility and comes in various colors.

The PAF-300 Series is characterized by:

● Environmental consciousness: Halogen-free ● Safety: Flame-resistant (UL-certified)

● Design: Comes in various colors. ● Functionality: Flexibility, low elasticity, low resilience, and low warpage

FA systems

◆Upgraded version of energy-saving reflow TNV series, TNV-Ver. III

TNV-Ver. III is an upgraded version of the energy-saving reflow TNV series. This product is equipped with convection control technology that efficiently circulates gas in the system, thereby reducing flux adhesion to the inner surface of the furnace and decreasing cleaning frequency and nitrogen consumption. Expanding the cleaning cycle improves customers’ productivity, and reductions in nitrogen onsumption and cleaning frequency allow for energy saving and resource saving, respectively.

TNV-Ver. III is an upgraded version of the energy-saving reflow TNV series. This product is equipped with convection control technology that efficiently circulates gas in the system, thereby reducing flux adhesion to the inner surface of the furnace and decreasing cleaning frequency and nitrogen consumption. Expanding the cleaning cycle improves customers’ productivity, and reductions in nitrogen onsumption and cleaning frequency allow for energy saving and resource saving, respectively.

◆Dual-lane twin-chamber reflow soldering system (TNV-MT7010CR)

The dual-lane twin-chamber reflow soldering system is an epoch-making soldering system in which two reflow soldering systems are combined into one. It has two independently driven conveyors and, as the inside of the chamber is partitioned, two different sets of temperature profiles can be set.

Compared to the case where two single-lane reflow soldering systems are installed, this system realizes 36% space savings and thus can contribute to the construction of your highly efficient production line by being combined with the dual mounter. Further, compared to the two single-lane reflow soldering systems, this system is equipped with an energy saving and heat insulation structure used in the TNV series, thereby realizing approximately 10% power consumption reduction in the stable state and approximately 12% reduction in integral power consumption. Furthermore, because its structure minimizes flux clogging even in mass production, maintenance performance is improved.

The dual-lane twin-chamber reflow soldering system is an epoch-making soldering system in which two reflow soldering systems are combined into one. It has two independently driven conveyors and, as the inside of the chamber is partitioned, two different sets of temperature profiles can be set.

Compared to the case where two single-lane reflow soldering systems are installed, this system realizes 36% space savings and thus can contribute to the construction of your highly efficient production line by being combined with the dual mounter. Further, compared to the two single-lane reflow soldering systems, this system is equipped with an energy saving and heat insulation structure used in the TNV series, thereby realizing approximately 10% power consumption reduction in the stable state and approximately 12% reduction in integral power consumption. Furthermore, because its structure minimizes flux clogging even in mass production, maintenance performance is improved.

|

|

|

◆Energy-saving N2 dual-reflow system (TNV-WD588CR)

A new N2 dual-reflow system with a dual lane conveyor mechanism has been added to the TNV series that has already been employed as energy-saving reflow systems by users. The N2 dual-reflow system has a two-lane conveyor that allows PCB mounting without relying on other systems, as the PCB mounting process typically requires two systems. It has the same time-tested energy-saving thermal insulation structure as the TNV series, thereby reducing power consumption by about 45% compared with two single-lane TNV systems. It also reduces footprint by about 45%. It has been adopted mainly by users associated with in-car products.

Information equipment

◆NTX Audio Mixing Consoles

NTX series audio mixing consoles is a digital mixing console suitable for live broadcasting and program recording. The main product in this series is X CORE, which is used to perform audio routing and audio signal processing. The X CORE has a MEDIA port that supports ST2110-30, AES67, and ST2022-7 standards, being compatible with IP-based next-generation broadcast systems. Compared to the NT Series, our previous audio mixing console series offering the same level of functionality, the main function sections (audio routing and audio signal processing sections) together use around 34% less power and the console uses around 68% less power, while the main function sections are smaller with controls placed closer together through high-density mounting.

NTX series audio mixing consoles is a digital mixing console suitable for live broadcasting and program recording. The main product in this series is X CORE, which is used to perform audio routing and audio signal processing. The X CORE has a MEDIA port that supports ST2110-30, AES67, and ST2022-7 standards, being compatible with IP-based next-generation broadcast systems. Compared to the NT Series, our previous audio mixing console series offering the same level of functionality, the main function sections (audio routing and audio signal processing sections) together use around 34% less power and the console uses around 68% less power, while the main function sections are smaller with controls placed closer together through high-density mounting.

|

|

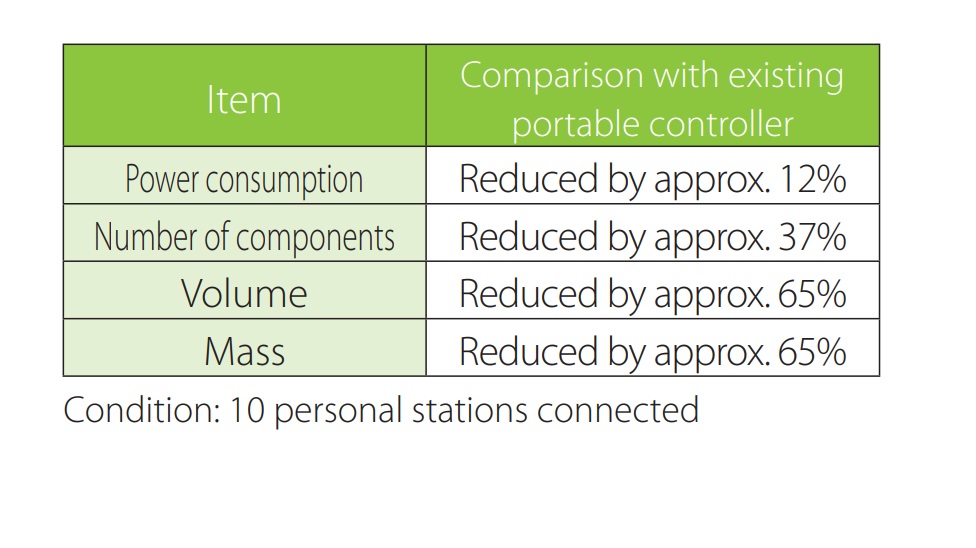

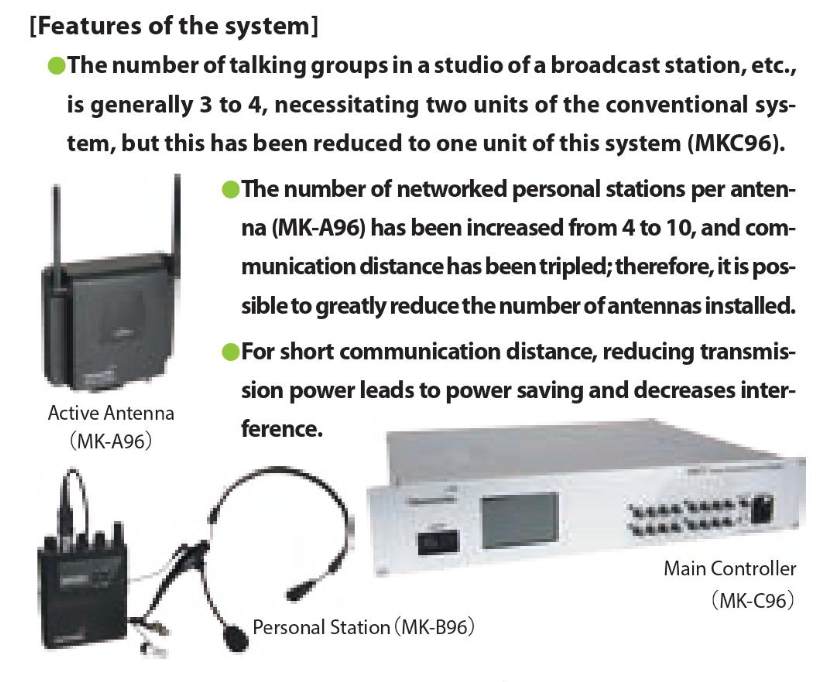

◆Portable DECT-based wireless intercom system

The portable DECT-based wireless intercom system, Tamura's new digital wireless intercom system, incorporates technologies accumulated for existing wireless intercom systems while complying with the new DECT standard.

It retains the same operability for intuitive use while offering further improved user-friendliness. Three units of the existing model (YFP-1821B) are required to connect 10 personal stations; meanwhile, one unit of the new model (MK-H96) can connect 10 personal stations. With the RF power setup function, it can save power and reduce radio waves that interfere with other devices when the communication distance is short.

The portable DECT-based wireless intercom system, Tamura's new digital wireless intercom system, incorporates technologies accumulated for existing wireless intercom systems while complying with the new DECT standard.

It retains the same operability for intuitive use while offering further improved user-friendliness. Three units of the existing model (YFP-1821B) are required to connect 10 personal stations; meanwhile, one unit of the new model (MK-H96) can connect 10 personal stations. With the RF power setup function, it can save power and reduce radio waves that interfere with other devices when the communication distance is short.

◆DECT-based Intercom System

The DECT-based Intercom System offers improved usability and allows development of larger systems than a conventional digital intercom system (PHS standard).

The DECT-based Intercom System offers improved usability and allows development of larger systems than a conventional digital intercom system (PHS standard).